cable and harness design The first, and most important step, of any electrical manufacturing process is pre-planned design. Same goes for developing a cable and harness assembly. Depending on the application, the engineers will have to take extensive measurements to know how much wire is needed between each connection. They also have to account for a little bit of “give” for each connection — you don’t want to struggle plugging in your connectors and break your painstaking wire work.  Every assembly is different, so for each new project there comes a new blueprint, but also new, exciting challenges! Prototyping is a common practice in the electronics manufacturing industry. Creating a test version of the final product is crucial in working out any kinks that weren’t ironed out in the design phase. Plus, prototyping gives the engineers a chance to get their hands on the real thing, which helps them to come up with more efficient layouts or refine their blueprints. Yahui is a professional wire harness assembly supplier in China. We have been in the wire harness industry for 13 years. Wire harness assembly is a very common thing for us. If you need wire harness processing or cable assembly, you can contact We, I believe you will not be disappointed.

Every assembly is different, so for each new project there comes a new blueprint, but also new, exciting challenges! Prototyping is a common practice in the electronics manufacturing industry. Creating a test version of the final product is crucial in working out any kinks that weren’t ironed out in the design phase. Plus, prototyping gives the engineers a chance to get their hands on the real thing, which helps them to come up with more efficient layouts or refine their blueprints. Yahui is a professional wire harness assembly supplier in China. We have been in the wire harness industry for 13 years. Wire harness assembly is a very common thing for us. If you need wire harness processing or cable assembly, you can contact We, I believe you will not be disappointed.

PROFESSIONAL

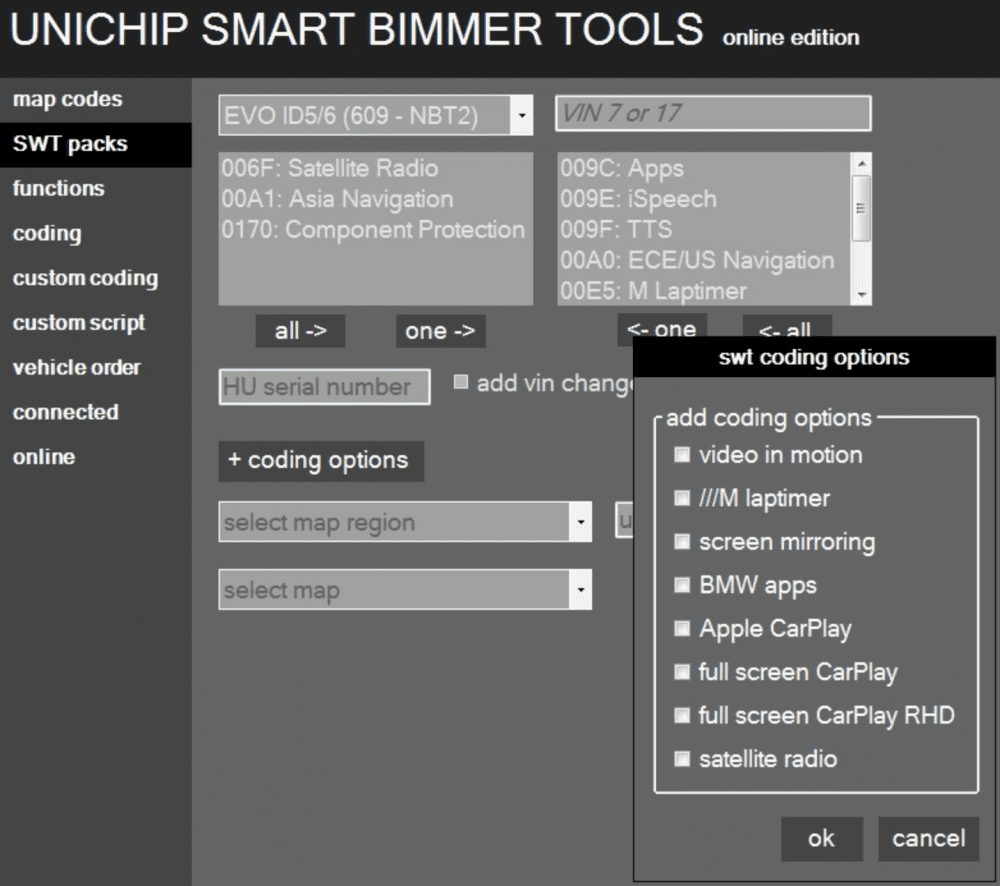

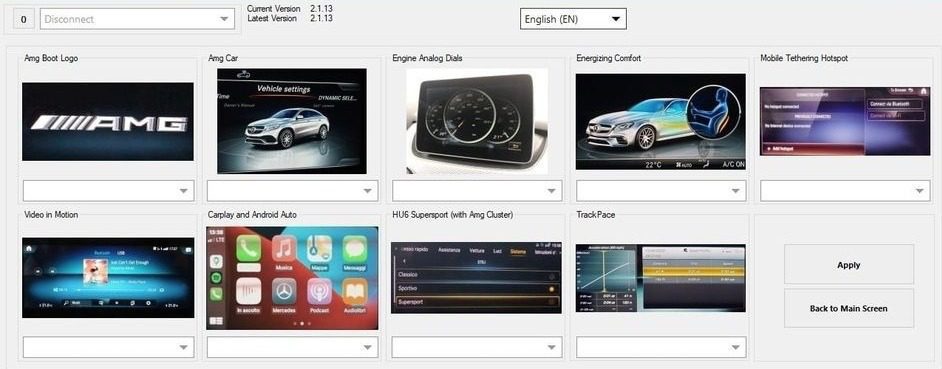

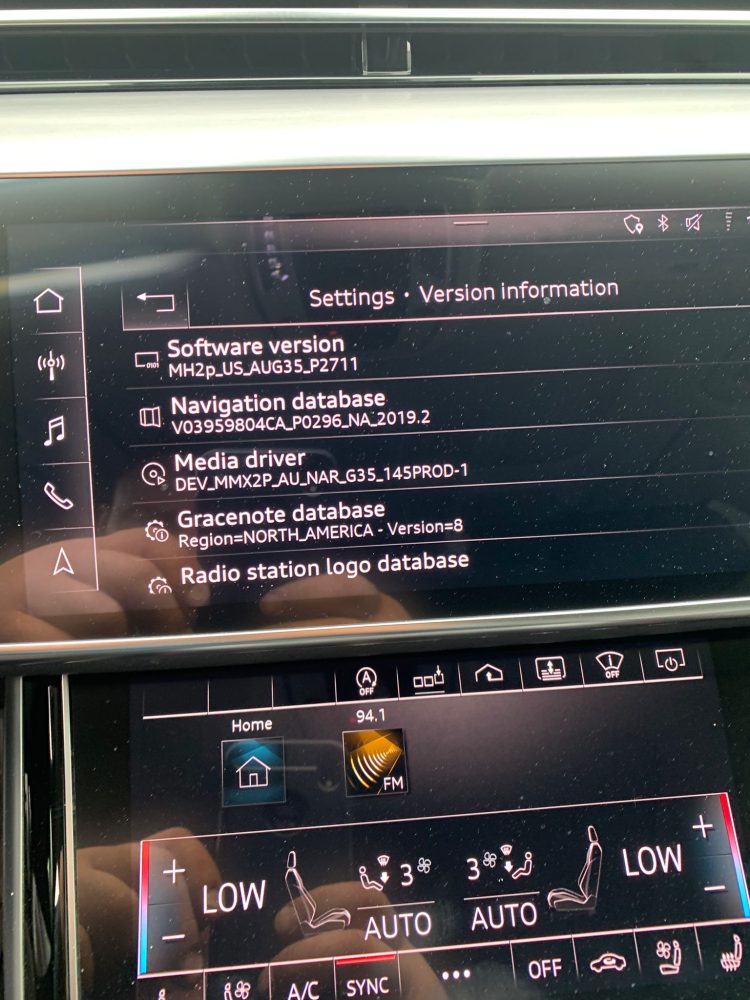

20 Years aftermarket technical support with dealer based diagnostic coding programming experience for BMW Mercedes Benz Audi Porsche Landrover, Tesla, Ferrari McLaren etc. Partnership with DIMSport, ACCINI, TEXA, BOSCH Diagnostic, ACTIA, AG Softing in Great China area.